- What does an air assist do for a laser cutter?

- Why Did We Test Different Air Assists?

- What Did We Test?

- How Did We Test?

- Test Results of the xTool D1 Pro 20W Air Assist System

- Test Results of the Sculpfun S10 (10W) Air Assist System

- Test Results of the Sculpfun S9 (5W) Air Assist System

- More Photos of the Results

- What About Using Air Assist Just for Laser Engraving?

- What About the Honeycomb?

- Conclusion

What does an air assist do for a laser cutter?

An air assist is a stream of compressed air that is blowing at the material being cut. The compressor provides air pressure, which helps to cool the material, preventing heat damage, and also helps to clear away any debris and smoke that is produced during the laser cutting process.

This allows for a cleaner and more precise cut and helps to extend the life of the laser cutter as it prevents the smoke from sticking to the laser lens. In addition, it can also prevent the material from catching fire during the laser cutting process, making your workplace much safer.

Why Did We Test Different Air Assists?

Air assist is used on laser cutters to help clear away debris, smoke and heat while laser cutting. This can be helpful in preventing charring of the material being cut, and also assists in providing a cleaner cut.

Nozzles and compressors can differ in size and shape, and all these parts can affect the performance of an air assist. In addition, the laser engraver optical power can also affect its efficiency. We have tested three popular laser engraving machines with and without it to see, which is the best option for different materials and cutting needs.

What Did We Test?

In this article we will review and test the air assist system on three different laser engraving machines – the 20W XTool D1 Pro, the 10W Sculpfun S10 and the 5W Sculpfun S9 which got the air assist upgrade kit just recently. Sculpfun and xTool use a similar air pump which has an output of 30L/min. They differ only in hose connector and speed controller. You can get the Sculpfun pump in with EU and US compatible version. The same applies for the xTool pump.

The xTool and Sculpfun are manufacturers that produce engraving machines that support the engraving control software called Lightburn and LaserGRBL and are very easy to use. We decided to test these three machines as they fall into three different price and power ranges.

This will give us some general overview on how well does an air assist perform with laser head that has a different optical power output. We will see how using it will benefit a lower powered laser beam compared to higher power laser beam coming from a higher power laser head.

How Did We Test?

We tried to cut a bunch of very thick materials with these three laser engravers with and without using an air assist to see, how much performance benefit does it bring to the table. We looked at the pure cutting performance increase and also the visual aspect of the results.

We will cut 10mm (3/5″) thick Poplar plywood, 15mm (5/8″) thick Paulownia wood, 17mm(11/16″) thick generic construction wood and 10mm (3/5″) thick black acrylic. We have also tried to push the xTool D1 Pro 20W to its limit and tried to to cut the 18mm (3/4″) thick poplar plywood using the air assist.

We did the cut tests at three speeds. 1800, 600 and 300 mm/min, but for the Sculpfun S9, we used only the slower two speeds, as the machine is the least powerful (5W) and it cannot cut at high speeds. Testing at different cutting speeds will give us some insight on what is the optimal speed for a certain machine.

Test Results of the xTool D1 Pro 20W Air Assist System

The xTool D1 Pro is a very common laser cutter engraver that found its way into many small business that make small batches for their customers. But it is also very popular between hobbyists as well, since it offers a lot of accessories like rotary tool for cylindrical objects, enclosure for ventilation, extension kit and much more. And thanks to its powerful quad-diode compressed spot laser head, it can be considered a true laser cutting machine. This machine screams quality and performance. The xTool D1 Pro already comes with the nozzle preinstalled, you just need to purchase the compressor, but the xTool D1 comes without the nozzle, but it is included in the assist upgrade kit. If you are interested in learning more about these two machines, you can read our reviews for the XTOOL D1 PRO and XTOOL D1.

First, look at a photo below, which shows the visual outcome of the pieces cut with the xTool D1 Pro 20W laser engraver with and without air assist. First thing you see is that cutting wood with air assist results with much cleaner edge and much less smoke stains on the surface near the edge where the cut was.

Below the photo, you will find an explanation with the analytical data with the exact number of passes needed to cut through a given piece at a certain speed.

10mm (3/5") thick Poplar plywood cutting test

With this material, the cutting performance of the xTool D1 Pro was similar with or without air assist, but the cut surface with the D1 Pro was much cleaner looking when using it, despite very little difference in number of passes needed to cut through compared to not using the air assistance.

The results:

- 1800mm/min: 17 passes without assist/ 16 with assist

- 600mm/min: 5 passes without assist/ 4 with assist

- 300mm/min: 3 passes without assist/ 2 with assist

15mm (5/8") thick Paulownia wood cutting test

This wood is lightweight and it is great for model making. Contrary to the previous test, the xTool D1 Pro 20W had much better cutting performance with the air assistance. Without using an it, there was a lot of charring for this wood.

The results:

- 1800mm/min: 25 passes without assist/ 10 with assist

- 600mm/min: >15 passes without assist/ 4 with assist

- 300mm/min: 5 passes without assist/ 2 with assist

If you would reduce speed even more, the xTool D1 Pro would be able to cut this thick wood in only one pass! This is a very capable laser cutting machine!

17mm(11/16") thick Pine wood cutting test

Next, we started cutting Pine (or Spruce) wood which is a cheap wood used for construction. This wood smokes a lot when cutting and the air assist was blowing a lot of dust away from the focus spot which helped the cutting performance a lot.

The results:

- 1800mm/min: 48 passes without assist/ 20 with assist

- 600mm/min: 9 passes without assist/ 5 with assist

- 300mm/min: 5 passes without assist/ 3 with assist

10mm (3/5") thick black acrylic. cutting test

The air assist is great for cutting acrylic as it helps to cool the material down, so it does not melt while cutting. This makes up for much cleaner cut, especially when making small parts where there is not enough time during multiple passes for the material to cool down.

The results:

- 1800mm/min: >50 passes without assist/ 37 with assist

- 600mm/min: 12 passes without assist/ 10 with assist

- 300mm/min: 6 passes without assist/ 5 with assist

18mm (3/4") thick Poplar plywood cutting test

For fun we also tried to cut 18mm thick poplar plywood board with the 20W xTool D1 Pro, but it did not manage to cut it even with the assist, although it came very close to making it through.

Test Results of the Sculpfun S10 (10W) Air Assist System

The Sculpfun S10 laser head is a dual-diode compressed spot module which pack a good punch for the buck! It also pack a bunch of features like expansion kit and rotary attachment for cylindrical objects and an affordable ventilation enclosure is also on the way. The Sculpfun S10 laser engraver already comes with an air assist set pre-installed, you only need to purchase the compressor. Read our Sculpfun S10 review if you want to learn more about this laser engraver.

Here is an photo of the test results comparing the visual outcome of the pieces cut with the Sculpfun S10 laser engraving machine. Below the photo, you will find an explanation with the analytical data with the exact number of passes needed to cut through a given piece at a certain speed.

10mm (3/5") thick Poplar plywood cutting test

With this material, the cutting performance of the Sculpfun S10 laser engraver was similar with or without air assist, but the surface cut with the air assist was brighter and there was less charring, There was also a notable improvement in cutting performance.

The results:

- 1800mm/min: >50 passes without assist/ 38 with assist

- 600mm/min: 9 passes without assist/ 7 with assist

- 300mm/min: 5 passes without assist/ 4 with assist

15mm (5/8") thick Paulownia wood cutting test

This wood is lightweight and it is great for model making. The Sculpfun S10 laser engraving machine showed slight improvement in cutting speed with the air assist. The cut was also much cleaner, especially with slower cutting speeds.

The results:

- 1800mm/min: >50 passes without assist/ >50 with assist

- 600mm/min: 8 passes without assist/ 7 with assist

- 300mm/min: 6 passes without assist/ 4 with assist

17mm(11/16") thick Pine wood cutting test

Next, we started cutting Pine (or Spruce) wood which is a cheap wood used for construction. This wood smokes a lot when laser cutting and the air assist provided a huge performance boost for the Sculpfun S10. The cuts made with it were also very clean. These are one of the cleanest cuts we have seen!

The results:

- 1800mm/min: >50 passes without assist/ >50 with assist

- 600mm/min: >25 passes without assist/ 11 with assist

- 300mm/min: >15 passes without assist/ 6 with assist

10mm (3/5") thick black acrylic cutting test

The air assist is great for cutting acrylic as it helps to cool the material down, so it does not melt while cutting. This makes up for much cleaner cut, especially when making small parts where there is not enough time during multiple passes for the material to cool down. The Sculpfun S10 showed substantial performance boost with the assist turned on!

The results:

- 1800mm/min: >50 passes without assist/ <50 with assist

- 600mm/min: 25 passes without assist/ 18 with assist

- 300mm/min: 11 passes without assist/ 9 with assist

Test Results of the Sculpfun S9 (5W) Air Assist System

Here is an photo of the test results comparing the visual outcome of the pieces cut with the Sculpfun S9 laser engraving machine. One might think that the S9 is more of an engraver machine than a laser cutter, because of its laser head outputs only 5W, but you are wrong! This engraver machine is in practice a very capable laser cutter! Read our review of the Sculpfun S9 to see what else can it do! The S9 originally comes only with a standard light shield, without the nozzle which you need to be purchase separately as an upgrade air assist set/kit with EU and US compatible air pump.

Below the photo, you will find an explanation with the analytical data with the exact number of passes needed to cut through a given piece at a certain speed. With Sculpfun S9 laser engraver, only the slower two speeds were used (600mm/min and 300mm/min) since this laser engraving machine is the least powerful and is unable to cut as fast as the other two laser engravers. But we also tested the performance on 6mm thick plywood.

6mm (1/4") and 10mm (3/5") thick Poplar plywood cutting test

With this material, the air assist did not affect the cutting speed of the Sculpfun S9 as much. But as with previous machines, the edge of the cut was much cleaner when using the assist.

The results:

6mm Poplar plywood:

- 600mm/min: 6 passes without assist/ 5 with assist

- 300mm/min: 3 passes without assist/ 2.5 with assist

10mm Poplar plywood:

- 600mm/min: 12 passes without assist/ 11 with assist

- 300mm/min: 5 passes without assist/ 5 with assist

The difference in number of passes was not as great as the Sculpfun S9 laser machine has some air management under the laser module when there is no air assist mounted as the fan which cools the laser module also directs some air to the working surface using a cone structure under the module.

15mm (5/8") thick Paulownia wood cutting test

This wood is lightweight and it is great for model making. The Sculpfun S9 engraver machine was cutting it very nicely at 300mm/min, With higher speed, the cutting performance was greatly affected.

The results:

- 600mm/min: >25 passes without assist/ >25 with assist

- 300mm/min: 6 passes without assist/ 5 with assist

Also in this case, the air assist provided the cleanest cut. This is especially apparent when looking from the side:

10mm (3/5") thick black acrylic

The air assist is great for cutting acrylic as it helps to cool the material down, so it does not melt while cutting. The Sculpfun S9 laser engraver struggled a bit with cutting the acrylic board this thick due to the low output power it has at its disposal. But it still managed to show good performance increase at cutting the black acrylic at low speed.

The results:

- 600mm/min: >25 passes without assist/ >25 with assist

- 300mm/min: >20 passes without assist/ 17 with assist

More Photos of the Results

You can clearly see the pattern here. The assisted cuts are generally less charred and much cleaner looking from the top and from the side.

What About Using Air Assist Just for Laser Engraving?

Air assist can also be used for laser engraving. It helps to improve the quality of the engraving by preventing the formation of soot on the surface of the material. In addition, it also helps to cool the material, which can minimize the risk of warping or melting. Although it is not absolutely necessary for laser engraving, it can be a helpful tool, particularly for materials that are sensitive to heat or prone to soot build-up.

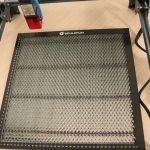

What About the Honeycomb?

Honeycomb is a must have accessory when laser cutting with an air assist. The compressed stream of air will puch the smoke through the material when it is about to get cut through. This smoke will stain the bottom of the wood and the bottom side of the cut pieces will not look clean at all.

Here is a photo of a test we did when cutting out a circle with honeycomb work bed vs. a standard solid steel plate as a working bed. You will see that when using the honeycomb mesh assures much cleaner part on both sides.

And another bonus when using the honeycomb is that the compressed air will not blow away your material when it is not held down with magnets or something else. We have also designed THESE HOLDING PINS which fit the Sculpfun honeycomb working table.

Air assist is great improvement for your laser engraver or cutter!

Conclusion

Air assist is an important part of the laser cutting process, and can provide cleaner cuts with minimal smoke stains and charring. In most cases it will also improve your cutting performance. It’s also an important safety feature, as the material being cut is less likely to catch fire. If you’re looking for a way to improve your laser cutting results, using air assist is a great place to start. You can save money buying upgrade kit for your favourite laser cutter engraver through the links below and using our discount coupon codes.

You can use my coupon code "JTxTool" for a 10% off at checkout for D1 Pro and accessories! Only for a limited amount of time and for a limited amount of orders!

Thanks for reading!

Sculpfun Air Assist KitxTool Air Assist Kit

That’s my next item to add to my pledge on Kickstarter. so I do have a question, how do I get on the giveaway and win some thing?

Thank you., Darius