- WeCreat Vision Review and Test

- Unboxing the WeCreat Vision

- WeCreat Air Purifier

- WeCreat Make It Software

- Plywood Engraving Test Pattern

- Anodized Aluminum Test Pattern - Measuring Precision and Laser Spot Size

- Testing the Autofocus Precision

- Focus Distance Test

- Plywood Cutting Test Pattern

- Testing the Camera Positioning Accuracy

- WeCreat Vision Giveaway!

- Is WeCreat Vision Worth it?

WeCreat Vision Review and Test

WeCreat Vision is a very simple to use laser engraver, great for anyone who wants to get into laser engraving without having to go through steep learning curve. Through this article we will explore its features and discover what WeCreat Vision can really do in terms of usability, performance and features.

Unboxing the WeCreat Vision

In the package you get a slat bed and some plywood boards, emergency stop switch, a good-looking chuck style rotary system, an automatic air assist pump and some other basic accessories. The rotary system looks very solid. Chuck style rotary has many advantages over the roller design as I have demonstrated in this article. Two test engravings are also included, proving that it was functionally tested in the factory.

It looks like a well-built machine. It features quality components and great attention to important stuff like cable management and safety. It has metallic rollers on all axis which should result in great mechanical precision which we are going to test.

On the back side there are the necessary interface connectors, exhaust outlet and Wi-Fi antenna. The emergency switch connects to the power adapter and will cut power to the machine if pressed.

The machine has autofocus system which adjusts the focus distance by rising the top part of the machine up and down. It can extend quite far up, allowing you to engrave big objects and use the rotary tool. Slat bed can be easily installed. This machine has a quite large engraving area. Inside, all the wiring is neatly arranged in cable chains.

On the lid, there are safety switches that detect if the lid is opened and stop the engraving process and protecting the user. The frame is also made out of a thick metal which makes the machine feel high quality and metal enclosure is also very welcoming, as in case of a wood catching fire inside, it will prevent fire from spreading.

WeCreat Air Purifier

You can also purchase an external air purifier which will eliminate almost all the smelly fumes, making it even safer.

It contains three filter stages – a large high efficiency carbon filter which effectively removes smell and dangerous compounds.

On top of it is the medium efficiency filter which is used to remove fine particles.

And on the very top is the coarse filter mesh, used to remove large particles and dust, extending the lifespan of the lower filter stages. The air purifier comes with two additional coarse filters.

Air exits on the side of the filter through these vents as it is clean enough to be exiting directly in a room.

The air purifier has a remote controller which has an infrared transmitter, so it only works on visual range, but it comes in very handy for turning filtering on and off. It has several speed settings, and it also has a timer. It is a very powerful filtration device, well worth the money.

WeCreat Make It Software

The machine uses their proprietary WeCreat Make It software which looks similar to the xTool Creative Space, but it feels like it has a bit less features. It is very easy to use. You can perform basic drawing tasks with ease, and it even provides some previews on what the engraving effect will look like in real life. Camera preview allows you to position the design quite precisely and using the autofocus, you don’t need to worry about focusing the machine.

WeCreat software also contains a large library of vector shapes and two hundred complete projects that you can start making right away. There is also a large library of projects available for purchase which are priced mostly at just one dollar which is a bargain compared to alternatives like Etsy..

But you are not limited to using only the WeCreat Make It software. You can make your designs in Lightburn which is what I use for making all of my standard engraving test patterns I use to test laser engravers.. You can define all the layers, settings and parameters, and export the g-code file. Then you import this file into WeCreat software, position it on the laser bed, set the material thickness and run the engraving.

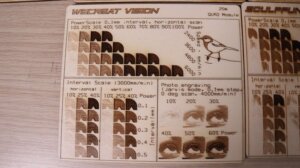

Plywood Engraving Test Pattern

My test pattern (you can download it here) is used to test the machine by engraving at different speeds and power levels, engraving at different interval settings in horizontal and vertical direction to see if the laser spot is not a perfect square, and lastly it contains the photo engraving test at different power levels.

WeCreat Vision has passed the engraving test with flying colors!

It produces very clear engravings with a lot of details and contrast and very little smoke stains thanks to the air assist. The interval scale shows very similar engraving performance in both horizontal and vertical engraving direction, which tells us that the focus spot is square shaped instead of it being a rectangle like it is often the case with some cheaper machines. Photo engravings also look very nice and detailed.

Compared to other machines in this power range, it has produced one of the best results so far.

Anodized Aluminum Test Pattern - Measuring Precision and Laser Spot Size

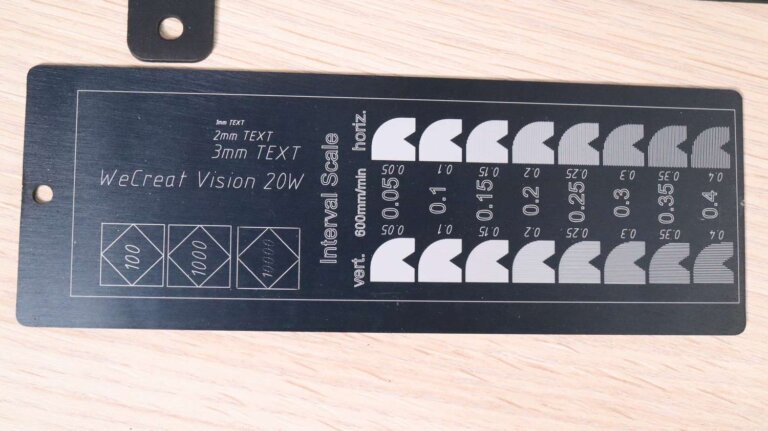

Then I ran my standard engraving test pattern on black anodized aluminum (you can download it here).

Engravings on this material are very crisp and I use this pattern to test the machine’s mechanical stability at different speeds and measure the laser spot size with the interval test pattern.

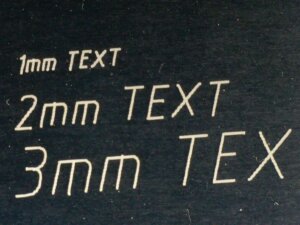

Looking at the small text engraving, we can see that WeCreat has an amazing precision for engraving small details. Even the smallest text is perfect.

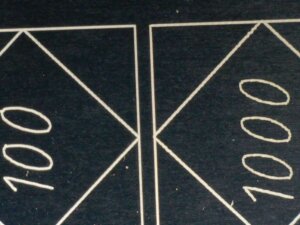

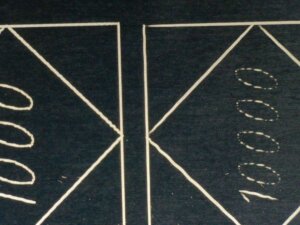

The three squares are engraved at different speeds ranging from 100 to ten thousand millimeters per minute which tests the machine’s mechanical stability. This machine is very stable at high speeds despite having a very high acceleration.

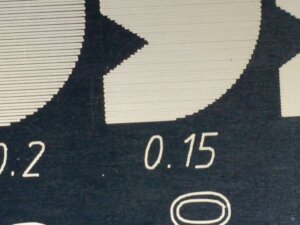

And the interval test shows us that the laser spot size is sized 0.15 millimeters in both directions. That makes it a perfect square which is ideal. There is slightly more overshoot when engraving in alternating directions in horizontal orientation which is probably due to the belt not being tight enough. But this is an easy fix.

Testing the Autofocus Precision

Then I went to test how precise is the autofocusing system. I have put an 18-millimeter-thick board in the machine and ran the autofocusing command. Then I moved the head back into position and measured the distance between the nozzle and surface, which was exactly 9 millimeters.

Then I have disabled the autofocus and focused the machine by manually entering the material thickness. In this case, the distance between the nozzle and the material was one millimeter less, resulting in an 8-millimeter distance. But one millimeter distance doesn’t have a big effect, and this proves that the camera based autofocus is doing its job very well.

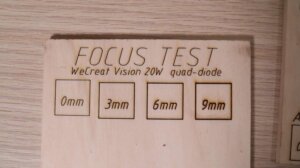

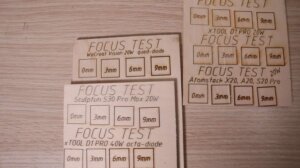

Focus Distance Test

Next, I have tested how well the machine retains focus which should be a good predictor of its thick material cutting performance. I did this test by enabling manual focusing, and changing the material thickness for each engraved square.

The first square is engraved at optimal focus and each subsequent square is engraved three millimeters higher than the previous square, which will help us to visualize how much the laser spot size increases inside thicker materials at laser cutting.

The results came out very good. This machine is good at retaining the focus at greater distances and should perform well at laser cutting thicker materials. Compared to other 20W machines, the WeCreat Vision is amongst the top performing machines in the focus retention test.

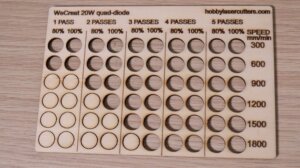

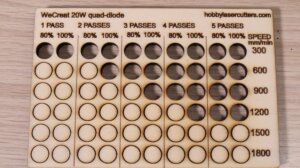

Plywood Cutting Test Pattern

I tested these assumptions with a plywood cutting test pattern (you can download it here).

I ran this cutting test pattern on 3mm(1/8″) and 6mm (1/4″) thick Poplar plywood. This test pattern tests the cutting performance at a few different speeds and number of passes to get a general idea of the cutting performance.

The WeCreat Vision performed very well for its power. When cutting 3mm plywood, it can almost compare to some 33W machines, which is incredible. But with only 20W it starts falling behind when cutting 6mm plywood. But considering that it is only 20W, the results are very good.

Here is how it compares to the other 33-40W machines I have tested with this pattern.

Testing the Camera Positioning Accuracy

Then I tried to engrave something on an anodized keychain tag. I positioned the design on the tag using the camera and engraved it. When it was done, I noticed that the positioning accuracy was not the best.

So I decided to do some testing to see what is the actual positioning accuracy using the built-in camera. I have drawn a few dots on a piece of scrap plywood and tried to engrave a cross on them using only camera positioning. I used manual focus for maximum precision and more consistency. Each dot was crossed on one corner of the machine plus the middle to see the approximate distribution of error across the workspace.

The left side of the machine had a significantly larger error, so I decided to run the camera calibration procedure which engraves some test patterns across the whole working area, and it then calibrated the camera across the entire focus adjustment range and across the entire workspace. Then, I redid my test and this time, the precision was much better. Camera positioning will never be ideal, but this is one of the best results I have seen using just a single camera for positioning.

WeCreat Vision Giveaway!

And now its time for the most anticipated part of the article as you are all probably wondering how to enter the free giveaway.

The rules for entry are straightforward: listen carefully to my narration through my YouTube video review and simply count how many times the word ‘WeCreat’ is mentioned in the entire video. Then, leave a comment on YouTube telling me your favorite feature of this laser engraver along with your count.”

Answers with only the number are not valid. If more of you will guess the correct number, I will select the winner with a random draw between those who answered correctly. And subscribe as I will reveal the winners in my next video in a couple of weeks.

All-in-one solution for simple laser engraving

Is WeCreat Vision Worth it?

WeCreat Vision is a laser engraver that is very simple to use. You don't need to be a very technical person to operate it. It is a fully enclosed design, seamlessly taking care of the harmful exhaust gasses so you don't have to worry about them like you have to with open frame designs.

The WeCreat Vision is a well built machine. It is fast and precise, thanks to good mechanics and very versatile with its rotary system and good autofocus.

Check out the WeCreat Vision by clicking on the button below. You can use my discount code "JTMakesIt" for 100$ off as a thank you for reading through the article!

You can also try the following codes:

"WECREAT" 5% off for all wecreat product!(Suit for accessories)

"WE20W" $100 off for wecreat vision 20w(including pack)

"WE40W" $120 off for wecreat vision 40w(including pack)

I would like to test it. I have a 33w output laser myself. I create my own disignes.

Great stuff

Thanks for all the detail

Looks really good