- Gweike Cloud Pro Review and Test

- Contents of This Review

- What Is the Gweike Cloud Pro and How Does It Compare to Glowforge?

- The Gweike Cloud Pro Vs Glowforge Laser Cutter

- Gweike Cloud Pro Features and Accessories

- Cutting and Engraving Different Materials

- Software and Supported Formats

- Gweike Cloud Pro Laser Engraving and Cutting Test Results

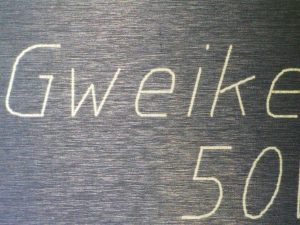

- Anodized Aluminium Engraving

- Laser Focus Distance Test

- Conclusion

Gweike Cloud Pro Review and Test

Contents of This Review

- What is the Gweike Cloud Pro and How Does It Compare to Glowforge?

- Gweike Cloud Pro vs Glowforge Pro

- Features and accessories

- What materials can Gweike Cloud Pro cut and engrave?

- Software

Gweike Cloud Pro Laser Engraving and Cutting Test Results:

- High speed test

- Plywood engraving test pattern

- Anodized Aluminum engraving

- Laser Focus Distance Test

- Acrylic Cutting and Engraving (transparent vs black)

- Plywood cutting

- Hardwood Cutting

- Engraving Stainless Steel

- Cutting white foam for model making

- Using the Rotary Roller Attachment to Engrave Transparent Glass Bottles

- Conclusion

What Is the Gweike Cloud Pro and How Does It Compare to Glowforge?

*The links on this website can be affiliate links. I earn a small commission at no extra cost to you. When you buy through these links you will support this website, which helps me to run this website(which cost money and a TON of time) and provide all these extensive reviews and information to you for free, without any paid membership.

The Gweike Company

The Gweike is a well established and mature manufacturer, specializing in industrial grade laser cutters with more than 18 years of experience in making laser cutters bigger than an average house in Europe. They definitely should know how to make great laser cutter!

Gweike Cloud Pro laser is their smallest and first consumer grade desktop laser cutter.

What comes in the package?

You get everything delivered on a big pallet. The Gweike Cloud Pro itself weighs 45kg (100lbs) and with all the extras the shipping weight is above 100kg.

But the machine comes very nicely packaged inside an industrial wooden crate.

Lifting the machine on the table is a two person job.

Aside from the machine itself, you also get an air filter box, inline duct fan and a generous Gweike material pack which contains cardboard, plywood, MDF and transparent acrylic material in a size of the machine bed.

Why did we choose Gweike Cloud Pro over Glowforge Pro?

After we have tested a ton of diode laser engravers and cutters, we wanted to make a step up and test a more powerful CO2 laser cutting machines that could fit the same type of work – hobby, crafts and small business. This means we needed an user friendly, simple to use CO2 laser cutter. First hit on google was of course a Glowforge. Machine seemed like a great fit, but we were greatly repelled by its steep price (5k$ for the mid-range model, 7k for the Pro model). But this was not the biggest issue.

When we got into details, we saw that the Glowforge can be only operated by their dedicated cloud software. So, no offline use and no Lightburn. The Glowforge cloud software is SEVERELY limited, you can’t rotate shapes and even draw a simple circle! For those “advanced” features you need to pay 50$ per month for premium account. That’s 600$ per year! Nope.

Plus, if anything breaks on the Glowforge, you need to send it back to United States for repair, since we are from EU, that would mean that we could be without the machine for weeks or months until it gets repaired. That was it, we were not getting it.

Then we found the The Gweike Cloud Pro. Already at a first glance, you can see that these two machines are direct competitors.

The Gweike Cloud Pro Vs Glowforge Laser Cutter

- SPEED: Gweike Cloud Pro is approximately 3 times faster than the Glowforge

- POWER: Gweike Cloud Pro is more powerful with laser tube that offers 50W of laser power, which is significantly more compared to the 40W laser tube from Glowforge

- WORK AREA: Both have approximately the same working area 20.08″ (510mm) *11.8″ (300mm) for the Gweike Cloud Pro vs 19.5″ (495 mm) *11″ (279 mm) for Glowforge

- SOFTWARE: Gweike can run with cloud or offline software and also supports Lightburn. Glowforge on the other hand can only be controlled with their cloud software which is very limited and requires additional paid upgrade. And the Glowforge can’t be run without active internet connection. This also means that if Glowforge goes out of business and they will no longer support their lasers, they will become just an expensive paperweight.

- SERVICEABILITY: Gweike is assembled with commonly available off the shelf parts which are easy to replace and they have active online support channel, providing repair guides and spare parts remotely, so that minor repairs can be fixed by the user or a local technician, without sending the laser to the service overseas. Glowforge on the other hand requires you to send the device to their service centre In US for any repairs which means that even for small malfunctions, you will need to pack the Glowforge and ship it and you will be left without it for long period of time (few weeks).

- CONSTRUCTION: Gweike has all metal enclosure with a glass top while the Glowforge has plastic enclosure. This makes the Gweike a bit safer in case of the material catching fire while laser cutting.

- ROTARY: Gweike Cloud Pro comes with two rotary attachments, Glowforge does not support rotary.

- PRICE: This is where Gweike wins completely as it costs less than half as much as the Glowforge ($3,199 for Gweike Cloud Pro vs $6995 for Glowforge Pro)

Gweike Cloud Pro Features and Accessories

Construction

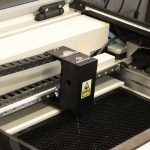

Gweike Cloud has a very solid all-metal construction. Inside, we can see that all axes feature industrial linear rails and very solid construction. The laser head has a removable protective cover which can be easily removed for maintenance. The Gweike Cloud Pro has a third, Z axis, for adjusting the focus via the software. Even the Z axis has a mini industrial linear rail!

Linear rails allows the Gweike to retain higher accuracy at very high speeds!

The Gweike Cloud Pro is built like a tank. The bottom part is made from solid aluminum plate across the entire machine!

Speed

The Gweike Cloud Pro is capable of engraving with very high speeds. With diode engravers you would normally use millimetres per minute for speed units, but CO2 lasers are much faster and normally speeds in millimetres per second are used.

The Gweike Cloud Pro can achieve speeds up to 600mm/s on x axis, which is a whopping 36000 mm/min! On y-axis it is a bit slower, as the y-axis is carrying a CO2 tube and it is much heavier. You can use this blistering fast speed for very fast photo engraving and fills.

CO2 laser tube and water cooling

It features water cooled 50W CO2 tube with outputs laser light in the far infrared spectrum with the wavelength of 10600nm. The CO2 vacuum tube sits on the y-axis gantry and the infrared laser beam is directed to the laser head where a mirror directs it through the lens which focuses it into the material.

The Gweike Cloud Pro laser cutter has a built-in closed water cooling system with a heat exchanger which is an advantage compared to cheaper CO2 lasers which need a bucket of water nearby for heat exchange.

Software and connectivity

The The Gweike Cloud Pro can be connected either on the Wi-Fi or with USB connection or you can use the LAN connection to have the machine accessible on your network. It can be controlled via at least three different types of software – the online Gweike cloud software, the Gweike offline software and Lightburn. You can find more details about the software further down in this article.

Motorized Z-axis for focusing

This machine has a third, Z axis, for adjusting the focus via the software. Even the Z axis has a mini industrial sliding rail! The Z axis assembly can be covered with the protection enclosure so less dust gets into the mechanism.

Air assist

Our version is the updated version of the Gweike Cloud laser cutter which has a built-in air assist pump which sits on the y-axis gantry. Older versions had the air pump inside the air filtration enclosure. That pump was loud and it was unable to be controlled on and off by the software.

The new air assist pump is almost silent and most certantly even more powerful.

Built-in camera for positioning

It has a built-in camera for positioning the designs on the material very precisely, which is very convenient. The camera has an additional USB output port at the back which is used to connect the camera to the computer for use with the Lightburn software.

Air filter box

The machine came with air filtration system and another spare filter, which we did not use much as it takes up a lot of space and we had the air vented outside. But We don’t think that the filter system is good enough to use the machine in the same room with no additional ventilation to the outside.

External air duct inline fan

With the machine you also get a very nice looking external inline air fan and longer hoses for better fume extraction. The hoses combined are more than 5m long. The fan is controlled by a wireless remote which is very nice and convenient. This fan is very strong and all the smell and fumes are extracted outside and the room stays fresh.

Rotary attachment

With the Gweike Cloud Pro you also get two rotary rollers, one for big and the other for smaller cylinders. They look pretty basic, but they look like they will do what you need them to do. And they have a nice scissor lift for adjusting the height.

Engraving boards that are larger than the machine

At the back it also has a slot for passing through material boards that exceed the machine dimensions. The front drawer lid can also be removed for this purpose.

Cutting and Engraving Different Materials

The CO2 powered Gweike Cloud can engrave all the materials that diode laser can: Wood, Cardboard, Plastic, Leather, Aluminum Oxide (anodized aluminum), Glass, Ceramics, Cotton Cloth, Slate.

It has much better performance when engraving transparent and white materials and a little bit worse performance at engraving stainless steel directly (which can be mitigated as described later down in the article).

The 50W CO2 Gweike Cloud Pro is also much faster and more versatile laser cutter than blue diode laser cutters.

It can cut cardboard, fabric, wood, MDF, acrylic…

Compared to the blue diode laser cutters, it is able to cut also the transparent and white materials (like plastics and foams) which is what diode lasers are not able to cut.

We have tested the machine with engraving and cutting different materials. You will find the results of our tests few chapters lower.

Software and Supported Formats

The machine can be controlled in at least three different ways – with their cloud software, their offline control software similar to Lightburn or with Lightburn itself.

Software is where Gweike wins compared to the Glowforge. Glowforge can only be controlled by their online cloud printing system, where if you want to draw anything more complex than a rectangle, you will need to pay extra for premium license. If the Glowforge has no access to the internet it will not work. And if Glowforge stops supporting their machine, or if they go out of business, their machines will be just a heavy paperweight.

But the Gweike will continue to work forever because it supports Lightburn and other Ruida control software.

Supported software is a major advantage of the Gweike Cloud compared to Glowforge.

The Cloud software

The easiest to use is with the Gweike Cloud software.

This is a simple interface meant to be used by non-engineers and artists. They offer a big library of free designs and its interface allows you to use all basic shapes and text and ready made graphics.

They also have a big library of user-added ready made designs and they even offer very affordable membership for even more added features.

If you use their materials which have a QR code, then you just need to insert the material, then the machine reads the QR code and adjust the cutting and engraving parameters automatically for optimal results. Of course you can use your own materials, but you need to adjust parameters by yourself which takes only few clicks.

This library is an amazing place to get very nice gift ideas which you can also customize, since you can add your own graphics on them.

You can also use the camera for tracing the existing shapes. With this feature you can capture different parts of your life and make them permanent. A very cool feature!

The Gweike offline software

The machine can also be controlled with their offline control software, which I didn’t use much because I am more used to Lightburn. But it looks like a fairly capable software! And its free!

Using the Gweike Cloud Pro with Lightburn Software

Using the Gweike Cloud with Lightburn is also very easy. Using the machine with Lightburn will allow you to unlock its full potential! You need the DSP version of the Lightburn license. Setting up the machine in Lightburn is simple and takes less than a minute.

If you want to use camera with Lightburn, you need to connect the camera with a separate USB cable to the computer.

Calibrating the camera takes a bit more work, but I will not go into details because there is a great tutorial online for this purpose. The camera needs to be calibrated with a printed piece of dotted pattern in various locations which tells the Lightburn the fisheye distortion of the camera. Then you engrave their test pattern and select the points so that Lightburn knows where everything is connected. Then the calibration is finished. You should expect approximately 1-2mm position accuracy which is enough for most of the work.

Gweike Cloud Pro Laser Engraving and Cutting Test Results

High speed test

The Gweike Cloud Pro can archive speeds up to 600mm/s which is a whopping 36000mm/min! We did a quick engraving test at 500mm/min to see how the engravings look like at different power levels.

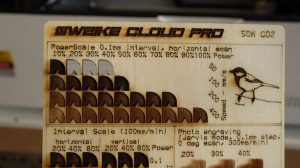

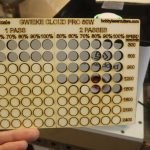

Plywood engraving test pattern

We have engraved our standard test pattern which is now modified to suit much faster and more powerful CO2 laser engravers. If you want to test your own laser, you can download the test patterns HERE!

Looking at the pattern, we can see that the Gweike Cloud Pro is very powerful as it burned through this 3mm plywood at low power when engraving at 50mm/s (3000mm/min) which is still very fast. And the photo engravings look amazing.

The Gweike Cloud Pro is a fast laser engraver! You really don’t need a lot of power when engraving at very fast speed which is great for extending the lifespan of the CO2 laser tube.

Power Scale test

The power scale test shows how the laser engraves at different speeds. The speeds selected here are now in millimetres per second as opposed to millimetres per minute as used by diode laser engravers (1mm/s = 60mm/min). We have used much faster speeds for this CO2 laser compared to our previous test patterns we have used for 5W, 10W and 20W diode laser engravers.

Interval Scale

For the interval test, the speeds are also increased, but “only” to 100mm/s. First time I tried to set these speeds at 300mm/s but I quickly realized that the Y-axis can’t achieve speeds this high as the y-axis is much heavier because it carries the CO2 tube and much heavier gantry overall. I redid the test with 100mm/s which was OK and still plenty fast.

This laser engraves very dark even at low power levels. Compared to diode laser engravers, CO2 laser shows a bit less dynamic range for engraving as the wood is darkened pretty much the same amount through various levels of power.

Photo Engraving

This laser is very good at photo engraving due to the high speeds it can achieve on x-axis.

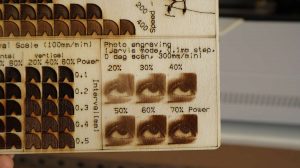

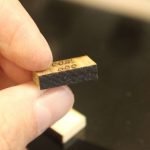

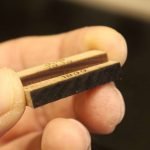

Anodized Aluminium Engraving

We have measured the laser focus spot size with the standard test pattern on anodized aluminium. If you want to test your own laser, you can download the test patterns HERE!

The most important part of this test is the interval test which enables us to evaluate the laser spot size as we will see later. The three test squares show how stable is the machine at cornering at different speeds. Here I have added another set of squares which are engraved at 10000mm/min to test the stability.

Let’s do some further lookup with the digital microscope. Here are the pictures taken with an Andonstar AD407 digital microscope.

The interval test shows us that the laser spot size is approximately 0.1 times 0.1 mm. As this is the point where lines become tightly packed together in the interval test pattern.

This machine is very stable even at higher speeds. It also performed very well at engraving very small text. The best so far over all the engravers we have tested!

Below is the engraving of two sets of squares on the right side, one inside the other. The outer square is engraved with 1000mm/min and the inner square is at 100mm/min.

These test squares show how stable is the machine at cornering at different speeds. Here I have added another set of squares which are engraved at 10000mm/min to test the stability.

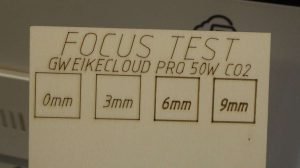

Laser Focus Distance Test

This machine has a motorized Z axis for adjusting the focus. The total focusing length is 17mm.

We performed our standard focusing test, which shows how big the laser spot becomes further away from the optimal focus. Thanks to the automatic Z axis adjustment, we were able to run this test in one go, since you can set the Z offset for each layer separately inside Lightburn. You can use this feature also when laser cutting thick materials as you can adjust the focus a bit lower for each pass for more optimal performance.

This machine has a bit larger focus spot size compared to the best diode lasers at distances of more than 6mm, but it makes up for that with more power.

You can use the thickening effect to your advantage in cases when you want to engrave bigger stuff with low detail. You set up the laser in this out of focus position. The beam will be larger and the engraving will be done faster this way as the distance between engraved lines can be bigger.

Acrylic Cutting and Engraving (Transparent vs. Black)

We have also performed the cutting test on acrylic with the the Gweike Cloud Pro laser cutter. Since the CO2 laser works in far infrared light spectrum of 10600nm it can also cut transparent materials.

We have performed a new type of cutting test pattern. It only tests the performance at one and two passes at multiple speeds.This type of test is more suited for the CO2 laser cutters which don’t require as many passes for cutting.

We have tested on black and transparent 3mm thick acrylic to see if there are any differences in cutting performance between the two colors.

The test has shown us that there is practically no difference at cutting performance between the two colors. During this test, I have left the air assist enabled, which causes some dust build up, which can be easily removed. I suggest that you leave air assist enabled only for laser cutting for better results.

I have also tried cutting 10mm thick acrylic at 600mm/min and Gweike was able to cut it in only 5 passes which is very good.

Laser cutting clean looking parts from transparent acrylic

To avoid having dust build up due to the air assist, you can leave the protection foil on the boards which is what you cannot do with diode laser cutters as they are not able to cut transparent foil.

To make a test more interesting, we have cut a simple box which was generated with a free online box generator.

The Gweike Cloud cuts acrylic like butter! We used 0.1mm kerf setting and the box was able to fit together nice and snugly. A perfect fit without the need of gluing it together. Very impressive! We will use this box for storing the honeycomb hold down pins to keep the material straight on the Gweike Cloud Pro honeycomb.

Plywood Cutting Test

We have also designed a new test pattern for testing the cutting performance of CO2 lasers. It tests the laser cutting performance at different speeds and power levels only for one and two passes as the CO2 lasers are much more powerful.

We have tested the cutting performance when cutting the 3mm and 6mm thick Poplar plywood. This machine cuts this plywood like butter.

We can see that it is much more optimal to set lower power and slightly slower speed for the same performance. This way, the CO2 tube lifetime will also be greatly extended.

For the 10mm thick Poplar plywood, I used the same method as before and the Gweike Cloud Pro has cut through it in 5 passes at 600mm/min and it needed 13 passes at 1800mm/min.

Hardwood Cutting Test

Tried to cut the standard hardwoods:

- 4mm Pine was cut in 1 pass at 600mm/min and in 3 passes at 1800mm/min

- 3mm Beech was cut in 1 pass at 600mm/min and in 2 passes at 1800mm/min

- 5mm Beech was cut in 3 passes at 600mm/min and in 5 passes at 1800mm/min

- 5mm Oak was cut in 2 passes at 600mm/min and in 5 passes at 1800mm/min

Engraving Stainless Steel

We also tried engraving stainless steel at 900mm/min at two different power levels and the result was good, but not the best. The result would be better if the surface was coated with CerMark or LaserBond prior engraving.

Fiber lasers and blue diode lasers are better at engraving stainless steel directly.

Cutting white foam used for model making

CO2 laser can also cut white colored foam for making model aircraft which is what diode lasers can’t. A while ago we made a set of RD model aircraft using laser cut foam with another (much worse performing) CO2 laser and it came out perfectly. Gweike should do even better.

Using the Rotary Roller Attachment to Engrave Transparent Glass Bottles

Since this machine is able to engrave transparent materials, it is also able to engrave glass directly. Lets take this opportunity to test the rotary system and try to engrave come cylindrical objects.

This machine comes with two rotary attachments, one for small and one for bigger cylinders. They look pretty basic, but they look like they will do what you need them to do. They have a nice scissor lift for adjusting the height.

To use the rotary you need to remove the honeycomb. Plug in the rotary wire and flip the rotary control switch and align the arrows on the y-axis gantry so that the laser head will run directly on top of the cylinder.

Glass is best engraved with lower power as the laser beam is causing the glass surface to crack. Lower power produces smaller cracks and better look overall. We have used too much power for this glass bottle (40% at 100mm/s) and the engravings were a bit too deep.

A serius laser cutter that leaves the Glowforge in its shadow!

Conclusion

Gweike Cloud Pro offers a lot for the money. It boasts very solid construction and bullet proof software support. Compared to 20W diode lasers, price per kilogram is unbelievable for this machine! Gweike Cloud Pro is an excellent machine for a very competitive price!

Compared to a blue diode laser engravers, CO2 laser can be used on more materials like transparent acrylic and glass, but it maybe lack some of the diode laser precision for power delivery when engraving detailed designs on wood.

But with loads of power and unmatched mechanical stability, the Gweike is much faster at laser cutting and engraving which is a huge plus if you want to cut a lot of parts or do a small production series.

With a machine like Gweike Cloud Pro you can easily start a laser engraving/cutting business, providing custom made laser cut gifts and ornaments for any occasion. Using their large Cloud design library or buying designs from sites like Etsy, making a customized gift is only a few clicks away! The Gweike Cloud laser will pay for itself in no time!

If you want to check another cool CO2 laser cutter, check out the review of the xTool P2!

You can use our Gweike Cloud Pro discount code "JT Makes It200" for 200$ off!

Be sure to also check out my reviews of newer laser engravers HERE!

This post was written by JT Makes It.

JT Makes It is an engineer, hobbyist, and DIY-er armed with a Master’s degree in Electrical Engineering and over a decade of professional experience in the industry. From an early age, JT Makes It was pushed by an insatiable curiosity, spending countless hours disassembling, understanding, improving, and creating various gadgets and products. This lifelong passion led to a broad spectrum of technical expertise ranging from electronics, woodworking, metalworking, and CNC machinery, with a particular focus on laser engravers.

For the past 9 years, he has shared his expertise through engaging videos on his YouTube channel. With the last three years dedicated to scrutinizing and testing laser engravers, he also created this website and emerged as a recognized authority in the field. His expertise extends across the spectrum of laser technologies, ranging from diode lasers, CO2 lasers, and fiber lasers, paying attention to details and providing practical insights.

With JT Makes It, expect a blend of technical expertise, backed with hands-on experience, and a genuine passion for innovation and creation, making him a trusted source in the realm of DIY and laser engraving enthusiasts alike.

Vielen Dank für den wunderbaren Test! Super!

Thanks!