Today, we’re putting two powerful laser engraving technologies head-to-head: UV lasers and fiber lasers. If you’re considering a laser engraver but aren’t sure which type best suits your needs, this video is for you! We’ll engrave a wide range of materials—including metal business cards, anodized aluminum, stainless steel, brass, copper, wood, acrylic, plastics, glass, stone, textiles, and more—to highlight the strengths and limitations of each laser type. The UV laser operates at a 355nm wavelength, while the fiber laser uses 1064nm, each interacting differently with various materials.

By the end of this article, you’ll have a clear understanding of what these machines can and can’t do, helping you make the right choice for your projects. Let’s get started!

Table of Contents

*The links on this website can be affiliate links. I earn a small commission at no extra cost to you. When you buy through these links you will support this website, which helps me to run this website(which cost money and a TON of time) and provide all these extensive reviews and information to you for free, without any paid membership.

UV vs Fiber Laser Engraver?

Fiber lasers and UV lasers both use galvo systems for high-speed, high-precision engravings, but they work in fundamentally different ways.

Fiber lasers operate in the infrared spectrum, meaning they generate heat to engrave and mark materials. They are best suited for metals and some plastics but struggle with delicate materials like glass and wood. In today’s article, fiber lasers will be represented by ComMarker B4 60W MOPA, ComMarker B6 60W MOPA and Monport GA60 60W MOPA. Click the links to read our full reviews of each of them!

UV lasers use ultraviolet light, which is absorbed by a wider range of materials, allowing them to engrave everything from metal and plastic to glass and textiles. Unlike fiber lasers, UV lasers rely on photo-chemical reactions rather than heat, making them ideal for heat-sensitive materials. UV lasers will be represented by the ComMarker Omni 1, 5W UV laser. Click the link to read our full review of this laser engraver!

Let’s put them to the test and see the real-world results!

Metal Engraving Comparison (UV Laser vs Fiber Laser)

Aluminum metal business cards

The fiber laser can produce deep, high-contrast engravings, leaving a crisp, permanent mark. Because fiber lasers have a lot of power, they can work incredibly fast, saving you time and money. They also work very quickly at cutting thicker metal cards (5 quick passes for 0.4mm thick card), allowing you to make a custom shape in a matter of seconds.

The UV laser, while being perfectly capable of engraving metal business cards, produces a shallower mark, which has a high contrast and high level of detail. But the 5W UV laser is almost unable to cut metals.

Although we were able to cut 0.4mm thick aluminum business card with a more powerful 10W ComMarker Omni 1:

Engraving raw aluminum, brass and copper:

The fiber laser excels here, creating deep, permanent engravings with a range of finishing options, from gentle frosting all the way to deep and dark markings. It can produce a wide range of engraving effects, and thanks to its high power, fiber laser can also produce deep 3D engravings in metals like brass.

The UV laser can mark these metals, but the engravings are less deep and typically you don’t have as many engraving effects at your disposal.

Although with a 10W UV laser, you can produce deep engravings in metal too. But it requires more passes and the process is much slower compared to fiber laser. here is a test on raw aluminum with the 10W ComMarker Omni 1:

Anodized aluminum is where both machines shine.

Fiber laser removes the anodized layer effortlessly, revealing the bright metal underneath. Thanks to its high power, it can work with incredible speed, spitting out engravings in seconds! A significant advantage of using a MOPA fiber laser is its capability to produce black and gray engravings on anodized aluminum which is not possible with a UV laser.

The UV laser also creates high-contrast markings on anodized aluminum, and due to its smaller laser spot size, it can produce even finer details. If you’re engraving intricate designs or tiny text, UV laser has a slight advantage here. But the difference is not big and can be seen only when engraving sub-millimeter details.

Engraving stainless steel

When it comes to engraving stainless steel, a fiber laser is the clear winner. Fiber lasers can either engrave deeply into stainless steel, producing very durable engravings that can stand the test of time. It can also produce pitch black surface engravings using a technique called black annealing which forms a very thin but durable oxide layer on the surface of the metal. This is great for marking knives or keychains.

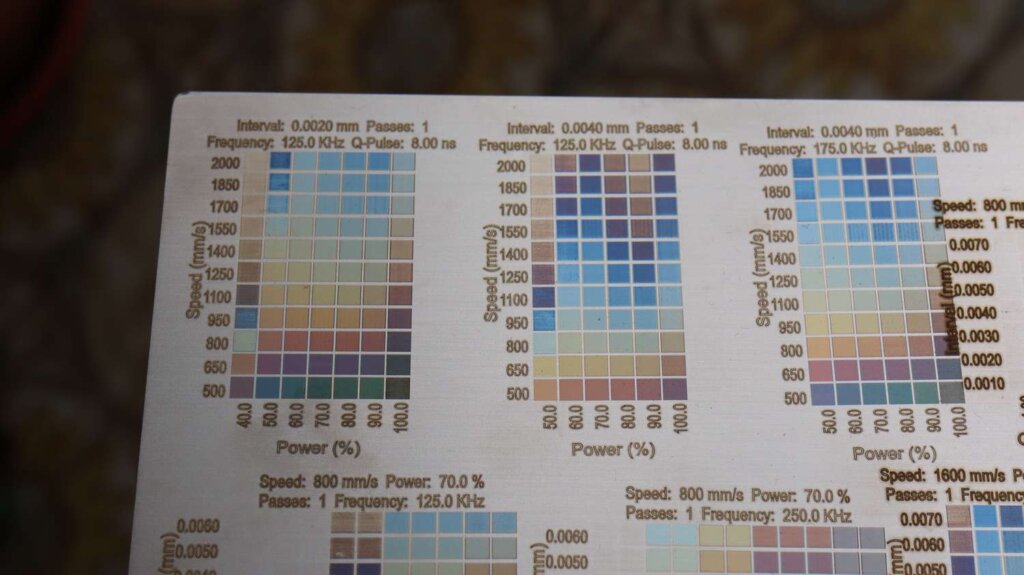

But if you choose a MOPA type fiber laser, you can produce a full spectrum of colors on stainless steel and titanium through annealing, which is done by heating the surface with very high precision which forms various thickness of the oxide layer, producing a full spectrum of colors.

In contrast, UV lasers are limited to shallower light engravings or slightly darker markings on stainless steel.

Engraving and Marking Plastic (UV Laser vs Fiber Laser)

Plastic is where the UV laser starts to shine.

On black acrylic, we have a tie between both machines. A UV laser produces a beautiful white engraving with high contrast. But fiber laser can also produce detailed and durable white engravings on black acrylic.

On colored acrylic, the UV laser delivers higher-quality engravings, while the fiber laser struggles, sometimes failing to mark at all.

On transparent acrylic, the UV laser wins for being able to engrave certain forms of transparent acrylic, while fiber lasers can’t mark transparent materials directly.

But on certain white plastics like this plastic power bank brick, both the UV and fiber laser were able to produce identical results. The same applies to some black plastics too, but it doesn’t apply to all of them.

Plastics are the area where UV lasers dominate. The fiber laser often melts the plastic rather than engraving it, potentially creating markings with less contrast. The UV laser, however, creates smooth, high-contrast engravings with minimal heat damage. This is especially noticeable on transparent and colored plastics, where fiber lasers struggle but UV lasers produce flawless results.

Laser Engraving and Cutting Glass (UV Laser vs. Fiber Laser)

Glass is notoriously difficult to engrave with most laser types, but let’s see how these two compare.

The UV laser is the clear winner here—it engraves glass with precision, creating a frosted effect without causing cracks. It is the only type of laser that can ablate glass directly. The result looks even better than sandblasting. This makes it perfect for custom glassware, awards, and decorative pieces. In some cases, I even managed to engrave in the middle of the glass, producing an embedded engraving. UV laser works so well on glass that it can even cut through it relatively quickly. With UV laser you can produce very deep, crystal clear engravings in glass.

UV laser can make perfect EMBEDDED engravings in the middle of the glass too! The “subscribe” text is embedded in the middle of that glass medal. Read more about this in the review of the 10W ComMarker Omni 1.

The fiber laser, however, struggles with glass. Glass is one of the biggest limitations of fiber lasers—it simply can’t engrave it effectively. If you want to engrave it, you need to use some dark interface material like the ceramic engraving paper, but the result is nowhere near as good as with UV laser. Plus, it takes a lot of extra preparation and cleanup.

Other types of lasers can only form micro surface cracks due to the applied heat. One common example of this is a CO2 laser:

How I design cool graphics without special knowledge?

If you’re like me and find graphic design challenging, Kittl.com is here to help you. Many of the designs featured in this article were created using Kittl, an online design platform packed with customizable templates for t-shirts, logos, posters, stickers, art, labels, and more. With its intuitive drag-and-drop editor, you can easily search for a design, select it, and modify it to your liking. Kittl offers over 1,400 free fonts available for commercial use, and adding additional elements is a breeze. Once you’re satisfied with your creation, you can export it in vector format, perfect for importing it into your favourite laser software and make awesome laser engraving projects. I highly recommend checking it out; you can register for free HERE.

Engraving Wood and Leather (UV vs Fiber Laser)

Engraving wood

Wood engraving is a challenge for fiber lasers since they rely on heat. The wavelength of fiber lasers isn’t well absorbed in wood. This is why they are either unable to mark wood at all or they leave a burnt, inconsistent mark.

The UV laser, however, engraves wood with extreme precision, creating detailed, crisp engravings without any smoke stains. A UV laser provides the cleanest and most detailed engraving on wood compared to any other type of laser. The only downside is that it doesn’t provide as much contrast as CO2 or diode laser as it does not burn the wood underneath.

Cutting Wood

Since publishing this article, we’ve also reviewed the 10W version of the ComMarker Omni 1 which is an excellent laser cutter for wood (and Mother of Pearl for inlays) which is what you can only dream of doing with a fiber laser. It cuts wood with ZERO burning, providing crisp and intricate parts.

Engraving leather

Leather engraves exceptionally well with a UV laser, producing clean, crisp results without any burn marks. UV lasers can create highly detailed engravings, ranging from shallow to deep, with exceptional precision and no charring.

Fiber lasers also work well on leather, offering a range of effects from dark to light engravings. However, because fiber lasers rely on heat, finer details can be lost in deeper engravings, and some burn marks are always present.

Engraving rubber and making stamps

Rubber engraving can be done with both lasers, although the UV laser produces a crisper engraving with more contrast.

Deep engravings are where the difference really shows. Here I wanted to make a rubber stamp using both lasers. I got the rubber sheets from Creatorally. Fiber laser engraves with heat, producing a rough engraving where small details can be lost, but simpler designs are still possible to make.

UV laser shows a clear advantage with deep engravings. UV laser can directly ablate the rubber, leaving a crisp engraving, retaining all the small details. Both lasers can be used to make deep engravings in rubber for making stamps, but the UV laser produces finer details with minimal heat damage.

Cutting high temperature gaskets

Also, if you want to cut high temperature gaskets, UV laser is the only laser that can do it effectively as high temperature gaskets can’t be cut by heat alone. For comparison, on the second picture I tried to make a cut with a fiber laser and a CO2 laser, both of which were unable to cut through even at slower speeds, and a blue diode laser didn’t work either.

Engraving Stone (UV vs. Fiber laser)

Some stones can be engraved with both lasers, but usually, the UV laser produces a shallower mark which has less contrast. This is because fiber lasers engrave with heat, which creates small fractures that result in deeper engraving.

Fiber lasers can produce deep engravings in stone quickly, making them ideal for custom gifts and awards.

UV lasers can engrave stone as well, but they create a lighter, shallower mark. Additionally, UV lasers can’t make as deep of engravings as with fiber lasers, but fiber lasers can’t engrave marble stone and crystals..

Since publishing this article, we’ve also reviewed the 10W version of the ComMarker Omni 1. Check this article as we managed to make much deeper engravings in stone with it! Below is an example of a deep engraving in stone done by a 10W UV laser with 15 passes at 500mm/s and a cutout of a Mother of Pearl inlay.

Engraving Textiles with UV and Fiber Lasers

Textiles, such as denim and even polyester, react far better to UV lasers, which can ablate the surface without burning holes or weakening the fabric. UV lasers produce exceptional engravings on fabrics, being able to ablate the dye and leaving the fibers below intact, retaining the strength of the fabric.

Fiber lasers generally struggle a lot to engrave textiles as their wavelength is not well absorbed in the fabrics. As you can see here, it can vaporize metals instantly, but doesn’t leave a single mark on denim.

Removing Rust (UV vs Fiber laser)

There are also some special uses and materials where one or the other machine excels. Fiber lasers are incredibly good for removing rust and cleaning out metal parts, leaving a pristine clean surface. But UV lasers can’t remove rust that effectively.

Engraving Ceramic Cups (UV vs Fiber Laser)

UV lasers are much better than fiber lasers at engraving ceramic cups, cleanly removing the paint and exposing the ceramic underneath. The top logo was done with a fiber laser, and the bottom one was engraved with a UV laser.

Engraving Cardboard and Dried Leaves With UV Laser

UV lasers are great at engraving materials like cardboard without causing burns. They can even engrave dried leaves while leaving the internal structure intact.

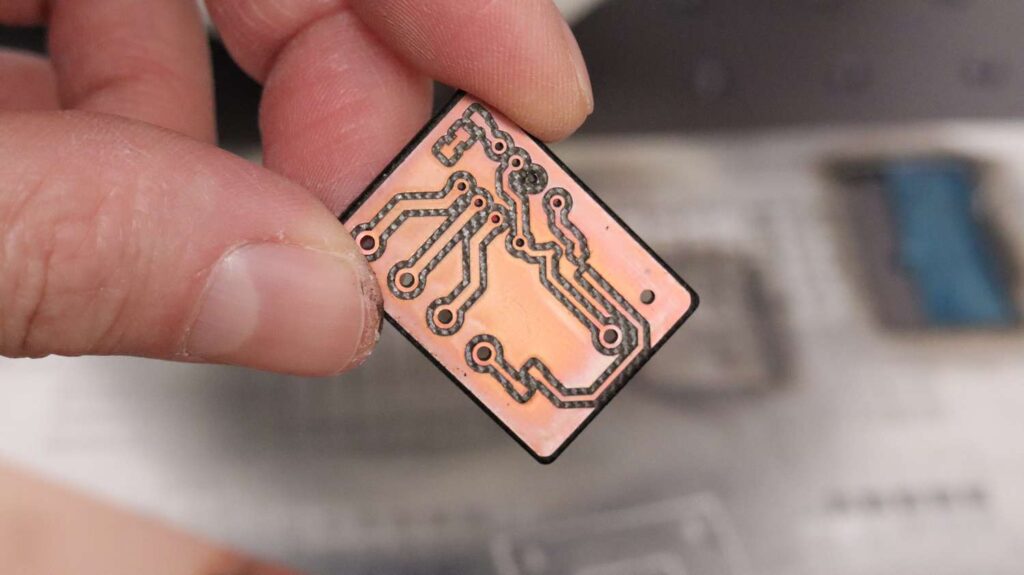

Laser Etching Printed Circuit Boards (PCBs) With a Fiber Laser

Fiber lasers on the other hand can be used to make prototype printed circuit boards, by being able to etch the copper, drill the holes and make the outline cutout in one go. This PCB for example was done in only 2 minutes by a 60-watt MOPA fiber laser. A great capability to have in case of needing a quick prototype.

Since publishing this article, we’ve also reviewed the 10W version of the ComMarker Omni 1. Be sure to check out the 10W model review to see what the 10W model can do! We also managed to etch a PCB with it with great results:

5W vs 10W UV Laser?

If you are further questioning the laser engraving performance between 5W and 10W ComMarker Omni 1, then you should also read our article where we compared the engraving performance differences between 5W and 10W ComMarker Omni 1 on more difficult to engrave materials.

Conclusion

If you need to engrave a wide variety of materials—including plastics, metals, glass, textiles, and wood—with high precision and minimal heat damage, a UV laser is the superior option.

Since publishing this article, we’ve also reviewed the 10W version of the ComMarker Omni 1. Be sure to check out the 10W model review to see what the 10W model can do!

Both machines have their strengths and weaknesses, and the right choice depends on your application. Hopefully, this article has helped you decide which laser type suits your needs best.

Laser engravers features in this article (click the links to read our detailed reviews):

ComMarker Omni 1 5W UV

ComMarker B4 60W MOPA

ComMarker B6 60W MOPA

Monport GA60 60W MOPA

But also check out:

Best laser engravers in 2024

xTool F1 Ultra dual beam laser

If you found this comparison helpful, don’t forget to subscribe to our newsletter mailing list to stay up to date with our laser-related content! Let me know in the comments which materials you’d like me to test next!

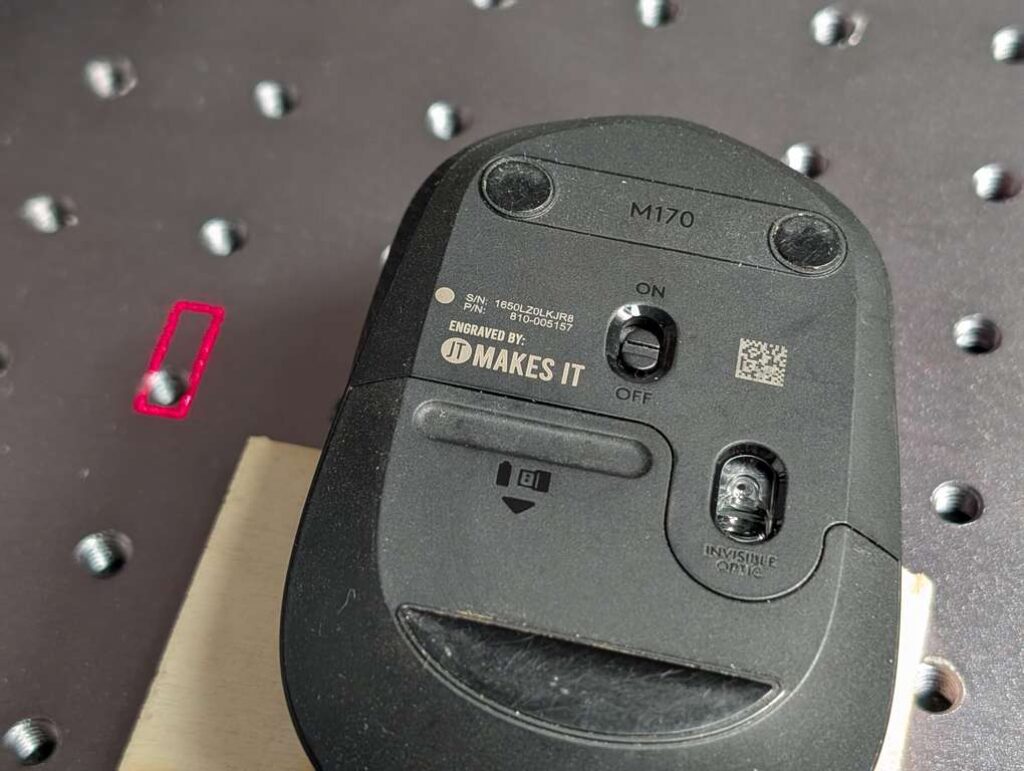

This post was written by JT Makes It.

JT Makes It is an engineer, hobbyist, and DIY-er armed with a Master’s degree in Electrical Engineering and over a decade of professional experience in the industry. From an early age, JT Makes It was pushed by an insatiable curiosity, spending countless hours disassembling, understanding, improving, and creating various gadgets and products. This lifelong passion led to a broad spectrum of technical expertise ranging from electronics, woodworking, metalworking, and CNC machinery, with a particular focus on laser engravers.

For the past 9 years, he has shared his expertise through engaging videos on his YouTube channel. With the last three years dedicated to scrutinizing and testing laser engravers, he also created this website and emerged as a recognized authority in the field. His expertise extends across the spectrum of laser technologies, ranging from diode lasers, CO2 lasers, and fiber lasers, paying attention to details and providing practical insights.

With JT Makes It, expect a blend of technical expertise, backed with hands-on experience, and a genuine passion for innovation and creation, making him a trusted source in the realm of DIY and laser engraving enthusiasts alike.

*The links on this website can be affiliate links. I earn a small commission at no extra cost to you. When you buy through these links you will support this website, which helps me to run this website(which cost money and a TON of time) and provide all these extensive reviews and information to you for free, without any paid membership.

Leave a Reply