- The Ultimate Guide to Making Money with Your Laser Engraving or Cutting Machine

- Stuff You Can Make With Entry Level 5W Diode Laser Engraver

- How Much More Capabilities Will a 10W Diode Laser Engraver Give You?

- Is a 20W Laser Engraver Worth the Extra Cost Compared to the 10W?

- Are State-Of-The-Art Octa-Diode 40W Laser Cutters Better Than a CO2 Laser?

- The Advantages of Adding an Infrared Diode Laser Module to your Blue Diode Laser Engraver

- If you want more speed for engraving metals, then look for a galvo system

- What Can a CO2 Laser Do That Blue Diode Laser Can’t?

- Galvo Fiber Laser Is Your Best Choice for Engraving Metal

- Conclusion

The Ultimate Guide to Making Money with Your Laser Engraving or Cutting Machine

Everyone craves custom made products and personalized gifts and because of that, laser engraving and laser cutting is becoming an appealing option for entrepreneurs, makers and hobbyists.

And whether you are a beginner wanting to start something new or you already have a machine at home and want to get some money back, there are endless opportunities to do it with any type of laser engraver or laser cutter. These machines are becoming more affordable every day and there is a machine for any budget. In this article you will learn how to make money with laser engraver (or cutter) of any type.

*The links on this website can be affiliate links. I earn a small commission at no extra cost to you. When you buy through these links you will support this website, which helps me to run this website(which cost money and a TON of time) and provide all these extensive reviews and information to you for free, without any paid membership.

Stuff You Can Make With Entry Level 5W Diode Laser Engraver

5W laser engraver is an entry-level budget option to get you into laser engraving business. These machines cost around 200-250$, depending on the amount of features the offer. On this website, we have reviewed a ton of them. The 5W optical power output is fairly low, these laser engravers are more hobby oriented, but you can still make money with a laser machine this cheap.

5W diode laser engraver pros and cons

Here are the pros and cons of the 5W diode laser engraver:

Pros:

- cheap/affordable

- easy to use

- can engrave wood, stone, anodized aluminum, stone, colored acrylic, plastics cloth…

- some high end 5W laser engravers can also engrave stainless steel like our favourite Sculpfun S9 and S30

- can cut thin wood, acrylic, cloth, paper

Cons:

- engraves relatively slowly

- cuts very slowly

- bad at cutting colored acrylics

- diode laser engraver can’t cut or engrave transparent, white and lightly colored materials and raw metals (with an exception to stainless steel with higher end machines)

If you want to do some laser cutting with 5W diode laser engraver, you should stick to 3mm plywood. Better ones like Sculpfun S9 can also cut 6mm or more, but they do it very slowly and need a lot of passes and you will be limited to smaller stuff otherwise it will take ages to cut.

How to make money with 5W diode laser engraver (laser engraving business ideas)

Since these laser engraving machines are slow (especially at laser cutting), you need to focus on low volume production or preferably making one-off customized gifts and products that don’t require a lot of laser cutting.

And you want to make stuff that has a lot of added value so you can get money in quickly. Best is to work in your local environment making customized birthday and wedding gifts, anniversary gifts for members of local association by engraving bought or handmade wooden items made by local woodworkers. This includes charcuterie boards, coasters and other decorative items. There are countless ways that you can earn money with your 5W laser engraver!

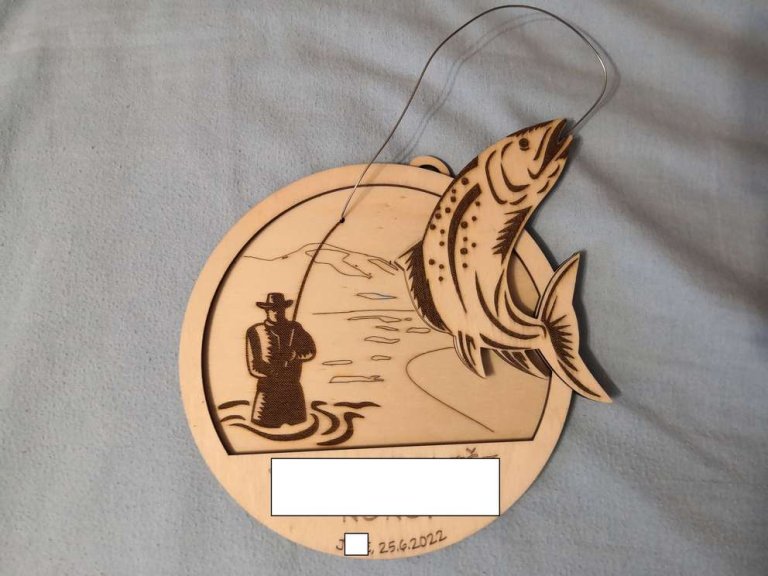

Here are some examples of what we have made with a 5W diode laser engraver:

- engrave on wooden cutting boards, wooden cooking utensils

- engrave phone cases

- cut paper art

- make rubber stamps

- engrave on thicker clothing

- cut wooden parts for RC model aircraft

- engraved on black anodized aluminum dog tags and military tags

- engrave on Charcuterie boards or coasters

If you want to learn how to convert photos to vector images like the one above watch the YouTube video on the top of this article where you will find a quick explanation on how to do it free and easy.

You don’t need to be a graphic designer to make nice and professional looking designs. I am not either and I use kittl.com to generate professional looking designs, shapes and text in minutes with no special knowledge of using complex graphical design software. You can also get a lot of cool vector designs on Etsy.com.

Caution! When buying a diode laser engraver, you should always look for optical output power specification since a lot of 5W laser machines are advertised as 20W to 60W “effective output” which means nothing. You can find some real life power measurements that we have performed on various popular 5W and 10W machines HERE.

How Much More Capabilities Will a 10W Diode Laser Engraver Give You?

Now you should have a feeling on what is possible to make with 5W laser and you are probably asking how much better would a 10W, dual-diode laser engraver be? They cost in a range of 400-500$ and in our opinion, they currently have the best price-performance ratio for starting out.

10W laser engravers combine laser light from two 5W laser diodes into one more powerful laser beam. With this kind of laser engraver you will be able do everything that 5W machine can do, but you will be able to engrave and cut faster. Plus, you will be able to cut thicker stuff.

Engraving performance of a 10W diode laser

As for engraving quality on wood, the 10W laser machine will produce similar quality compared to 5W engraver. But you will be able to engrave much faster which makes a huge difference when engraving bitmap photos which take a very long time. When engraving solid hardwood boards you will see that the more powerful machine will produce deeper engravings that look a bit more premium.

The biggest advantage of the 10W laser engraver is that with this amount of power you are able to engrave stainless steel directly with nice and reliable results.

They are also great at engraving on back side of a mirror. Engraving process removes the coating and the mirror becomes transparent for the light comming from the back. Placing a light behind the mirror can make a cool effect!

You can also laser engrave glass (which needs to be temporarily painted black so the laser beam has something to “grab”. You can check out the photo of a glass engraving made with a 20W laser engraver a bit further down this article.

Cutting performance of a 10W diode laser

With 10W laser machine you can cut much faster and cut thicker stuff. These laser machines cut 3mm and 6mm plywood like butter, you can also cut 10mm thick softer woods reliably. The cuts are much cleaner and there is less charring on the edges which make a cleaner looking end product. 10W is also enough to reliably cut leather.

Another big difference is when cutting colored acrylic as the 10W laser machine doesn’t struggle as much as the 5W machines do.

With machines which have optical power output of 10W or more we recommend buying air assist upgrade (if the machine does not already have it). It will speed up laser cutting and produce cleaner cuts with less charring. Another safety feature the air assist provides is that it extinguishes a flame which occurs if your material catches fire while cutting. But you still shouldn’t leave the machine running unattended. HERE you can learn more about our air assist tests.

If you use air assist system, then you also need to get a honeycomb bed which will allow the air and smoke to escape underneath. Otherwise the bottom side will get a lot of smoke stains.

10W diode laser engraver pros and cons

A 10W laser engraver is a best bang for the buck currently and offers a lot of capabilities for the price.

Pros:

- still reasonably priced

- easy to use

- can engrave everything a 5W machine can plus it can also engrave some more difficult materials like stainless steel, glass(painted black) and backside of a mirror…

- can cut thicker wood, acrylic, cloth, paper, dark EVA foam,..

- air assist makes a difference when cutting

Cons:

- still bad cutting performance compared to CO2 lasers

- diode laser engraver can’t cut or engrave transparent, white and lightly colored materials and raw metals other than stainless steel and titanium

How to make money with 10W diode laser engraver

Let’s discuss some laser engraving business ideas that will enable you to earn some money with your 10W laser engraver. With 10W of optical power you can do everything that we have described that can be done with 5W machine, but you will be able to do it faster. You will be able to make more products in the same time, which opens up the doors to a small scale production quantities.

10W machines often have better mechanical stability and are great for engraving on metal business cards, key chains and animal tags. If you want to use high quality, American made tags, you can get them at Chewbarka.com. Also, if you send them an email and say that “JT Makes It” sent you they will give you 25$ free store credit to try out their products!

Since 10W is enough to do some more laser cutting, you can also make some cool wooden or acrylic boxes. There is a great online generator where you can generate a box of any dimension in just a few minutes.

Great niche business idea for making money with a laser is making wooden wedding badges. People spare no expenses for a perfect wedding. Wooden badges are small and quick to engrave and cut. With a 10W of power you can make a lot of them in a single day.

You can also make custom gifts for the bride and groom, like this heart shaped box which you can easily generate with an online box generator. You can also get a lot of cool vector designs on Etsy.com. if you have a 10W machine, making money with a laser is a very tempting idea!

You don’t need to be a graphic designer to make nice and professional looking designs. I am not either and I use kittl.com to generate professional looking designs, shapes and text in minutes with no special knowledge of using complex graphical design software.

What are some good 10W laser engravers?

We have reviewed a lot of 10W laser engravers.

- Best bang for the buck goes to the Sculpfun S10 and its newer brother, the Sculpfun S30 Pro.

- The most feature rich was the Atomstack A10. T

- The highest quality award goes to the xTool D1

- The best budget option was the Comgrow Comgo Z1.

Check out the full list of the machines we have tested.

Is a 20W Laser Engraver Worth the Extra Cost Compared to the 10W?

20W laser engraver is going to speed up your laser engraving business and open new doors and possibilities. With 20W quad-diode laser engraver you will be able to engrave faster, deeper and cut thicker materials with ease.

20W laser machine will currently set you back by approximately 800-1000$. These are state-of-the-art diode laser engravers, with all the bells and whistles.

Engraving performance of a 20W diode laser

For engraving on wood, you get a speed improvement when you want to make deeper engravings. 20W laser engraving machines usually have improved mechanical parts and allow faster movements. This is especially noticeable when trying to engrave bitmap photos which take a lot of time.

With 20W laser engraving machine you get a lot of speed improvement when trying to engrave on difficult to engrave materials like stainless steel, stone, some metal coatings, glass(painted black), deep leather engravings, ceramics…

Cutting performance of a 20W diode laser

20W laser machines cut very well. They are at least 4 times faster than 5W lasers. They cut thin 3mm plywood in a single pass, 6mm plywood in 2 passes at 600mm/min and can cut up to 15mm thick wood with reasonable speed.

When laser cutting with 20W laser engraver, you need an air assist which helps to cut faster and produce cleaner cuts with less charring. It also prevents the material from catching fire to some degree. And honeycomb is also necessary to prevent smoke staining of the bottom side by allowing the air and smoke to escape underneath the material which doesn’t stain the underside and small wooden pieces don’t get blown away by the air.

They are very good at cutting black and colored acrylic and with a machine like this, you will be able to cut larger designs relatively quickly.

20W diode laser engraver pros and cons

20W laser engraver will speed up your hobby or money making business and enable you to produce things much faster and efficiently.

Pros:

- affordable for a small business

- easy to use

- can engrave everything a 5W and 10W machine can, only much faster and cleaner

- can cut much thicker materials cleanly with less charring

- air assist makes a difference when cutting

- it can engrave difficult materials (like stainless steel) very quickly, saving a lot of time

- much faster when cutting acrylics

- require little maintenance compared to CO2 lasers

- long lifespan

Cons:

- rather expensive for a hobby

- cutting performance still not comparable to CO2 lasers, but we are getting closer

- diode laser engraver can’t cut or engrave transparent, white and lightly colored materials and raw metals other than stainless steel and titanium

How to make money with 20W diode laser engraver

Making money with 20W laser engraving machine is a great way for starting a profitable laser engraving business. Since they are much faster, you will be able to produce significant quantities of products in a small amount of time. You can offer laser and engraving products and services locally or you can even make your own online store, where you can sell laser engraved products all over the world. Making money with a laser with this much power is an easy task.

Depending on the size of the products you will be cutting or engraving, you can reach triple digit production quantities. Of course you can make everything that can be done with a 10W and 5W laser engraving machine. Don’t forget to check above in this article for cool business ideas with these machines too.

You can still do one-off customized products that big players don’t have time to deal with. By offering more customization options to clients, you can charge a lot for a single design. You don’t need to be a graphic designer to make nice and professional looking designs. I am not either and I use kittl.com to generate professional looking designs, shapes and text in minutes with no special knowledge of using complex graphical design software. You can also get a lot of cool vector designs on Etsy.com. You can also sell your designs there by setting up your own Etsy shop!

You can also buy expansion kits for diode laser engravers. Here we have used the full expansion kit for the Sculpfun S30 Pro Max to cut a big wall art out of a thick paper. Having more power makes it easier to cut large designs quickly, as it could take a lot of time with the lower powered machine.

What are some good 20W laser engravers?

- The best cutting performance was delivered by the Sculpfun S30 Pro Max

- The xTool D1 Pro 20W appears to be more premium looking and reliable.

Check out the full list of the machines we have tested.

Are State-Of-The-Art Octa-Diode 40W Laser Cutters Better Than a CO2 Laser?

This year, the xTool introduced the world’s first 40W octa-diode laser engraving machine. Eight diodes focused into one strong laser beam is a cutting edge laser technology! No pun intended 🙂 With 40W of optical power it is well in the range of CO2 laser cutters, but because diode lasers output a laser light of different wavelength compared to CO2 laser machine, they still behave a bit differently and can be used for different purposes.

And Sculpfun has also just released a 33W hexa-diode laser engraver, the Sculpfun S30 Ultra which offers a slightly larger footprint of the working area. We will soon review it. Subscribe to our newsletter to get notified when we release a new article/review (approx once a month)

Engraving performance of a 40W diode laser engraver

The 40W upgrade kit for the xTool D1 Pro is truly impressive! It contains not only the 40W laser module but also a new motherboard and the improved X-axis which allow the machine to reach speeds up to 400mm/s (24000mm/min) which is blazing fast! You can engraved products almost as fast as with comparable CO2 laser cutters like the Gweike Cloud Pro which we have reviewed earlier! Fun fact: the xTool is twice as fast as Glowforge Pro!

Combining the incredible speed with a powerful laser module, you can engrave very fast which is ideal for making your laser engraving business profitable since time is money! You can make a ton of engraved products in very little time as the engraving duration is reduced significantly!

Just about any material that can be engraved with a diode laser engraver can be engraved with high speed using this machine. Stone, stainless steel, acrylic, wood, ceramic, back side of mirrors, darkened glass…

Cutting performance of a 40W diode laser cutter

40W diode laser cutting machine is performing very close to CO2 laser cutters. The 40W xTool D1 Pro is not far behind the 50W CO2 Gweike Cloud Pro laser cutter we have reviewed a few weeks earlier.

It also cuts colored acrylic like butter! You can cut large designs out of acrylic in a short time which is impossible to do by using weaker modules.

This module also retains focused beam across a very large distance and it we were able to cut wooden boards up to 40mm thick with this module! This is something that CO2 lasers can’t do as they have a shorter focused range.

40W laser engraver pros and cons

Pros:

- affordable for a small business

- easy to use

- can engrave everything a 5W, 10W and 20W machine can, only much faster and cleaner

- cutting performance is almost comparable to CO2 lasers

- retains tight focus across very large distance which enables it to cut VERY thick stuff (thicker than CO2 laser)

- air assist makes a lot of difference when cutting

- it can engrave difficult materials (like stainless steel) very quickly, saving a lot of time

- much faster when cutting acrylics

- require little maintenance compared to CO2 lasers

- it can engrave as fast as CO2 lasers

- long lifespan

Cons:

- rather expensive for a hobby

- slightly larger focus spot than lower powered machines. But not by much.

- diode laser engraver can’t cut or engrave transparent, white and lightly colored materials and raw metals other than stainless steel

40W diode laser engraving business ideas

This machines performance is comparable to CO2 lasers. The advantage is that it is lighter, more portable and requires less maintenance and should have a long lifespan. It will make your hobby a profitable business venture. With a engraving machine like this you can also offer engraving services outside, on a popular tourist spot, engraving custom souvenirs to tourists in real time thanks to its speed. Not that is what we call a new-age laser business niche! No one has thought of making money like this!

Since it can cut very quickly, you can create a lot of custom gift or decoration boxes with this cool online box generator. You can also get a lot of cool vector designs on Etsy.com. And you can make professional looking graphical designs with just a few clicks using kittl.com. You will get a lot of gift ideas there.

The Advantages of Adding an Infrared Diode Laser Module to your Blue Diode Laser Engraver

One downside of a blue diode laser is its inability to mark raw metals other than stainless steel and titanium sice the blue light bounces off the metal surface like nothing happened.

The xTool has solved this problem by introducing the infrared diode laser module. We have also reviewed this xTool infrared module. Read this article to see what infrared laser can really do.

Instead of emitting 450nm blue light, it emits 1064nm infrared light. This is the same wavelength as the fiber lasers produce which is the best for marking metal.

This infrared module has only 2W of power, but it engraves metals like butter which is what blue diode and CO2 lasers can’t. It can engrave aluminum, brass, copper, stainless, titanium, gold, silver, chrome….

It can also produce very nice looking engravings on certain plastics which have a lot more contrast compared to engraving with blue laser light.

Infrared laser modules have much smaller laser spot which makes them ideal for engraving with great precision on jewellery and small animal tags. It is a great addition to make your laser engraving business more profitable.

Infrared diode laser pros and cons

Pros:

- can engrave raw metals that blue diode and CO2 lasers can’t (aluminum, brass, copper, steel, stainless, gold silver, chrome (jewellery)

- has a very small focus spot. Much smaller than blue diode.

- can produce very good engravings on acrylic and other plastics(also white)

- can engrave metals very quickly

- smaller investment (just buying an additional module for the existing machine frame

Cons:

- not as fast as galvo laser

- not as powerful as fiber laser

- can’t produce very deep engravings

- slow (compared to galvo fiber lasers)

If you want more speed for engraving metals, then look for a galvo system

If you wish your infrared laser engraver would be faster, then you should look at a machine like Enjoywood M4. It is basically the xTool infrared module, paired to the galvo mirror system that directs the laser beam on a surface without using external moving parts.

A machine like this is up to 50 times faster than conventional mechanical gantry style machine. But it has one downside and that is a very small working area of 7cm square. This is why it is more suitable for making small marks like logos, QR codes on keychains and other small items.

It can do everything the xTool infrared module can, just faster. One downside is that it is more expensive and has a much smaller working area.

I have also used this machine for engraving custom characters on backlit laptop keyboard keys. The result is indistinguishable from the factory engraving. let’s see if you can spot the extra character 🙂

What Can a CO2 Laser Do That Blue Diode Laser Can’t?

CO2 lasers were around long before diode laser engraving machine came to be. They are considered the golden standard. The laser beam is produced with a vacuum tube which needs high voltage power and it also needs to be water cooled. This is why CO2 lasers are more complicated, larger and more expensive. Entry range offers 40-50W of optical power output. Here we have used the Gweike Cloud Pro 50W CO2 laser cutter which is a cheaper Glowforge alternative which is better than Glowforge in almost every way. But we have also tested and reviewed the xTool P2 and were even more impressed with it. Read our full review to see for yourself!

Compared to diode modules, the CO2 laser has much longer wavelength of laser light (10600nm compared to 450nm from blue diode modules). This is far infrared light and is invisible to naked eye. Different materials absorb light differently, which affects the performance of engraving and cutting.

Engraving performance of CO2 lasers

CO2 laser tube is very large and it usually sits either stationary on the side of the machine or on the Y-axis gantry. The beam is directed into the cutting head with a set of mirrors. This means that the laser head can be very light and consequently this types of machines are able to engrave very fast. They are able to engrave with speeds from 400mm/s to 1000mm/s or more. They can produce deep engravings which can sometimes have a bit less contrast compared to slower diode engravers. They also engrave leather very well.

CO2 lasers excel at filling shapes line by line like an inkjet printers due to their high speed, but are not as great at vector engraving as the CO2 tube makes it more difficult to precisely reduce power when slowing down in corners, making them over-burned sometimes.

By not having a visible beam, CO2 laser is also more difficult to precisely position design for engraving on small objects like spoons and pens. Some CO2 lasers offer cameras for positioning which work, but the position precision is not perfect.

CO2 lasers can engrave acrylic similarly to diode lasers with an exception that they can engrave white and transparent colors too.

They can’t engrave any type of metal, but they can engrave stainless steel, but the result is not as good as with diode lasers and much worse than infrared and fiber lasers. You can get around this with covering the surface some expensive chemicals.

But CO2 lasers can remove anodized coatings and paint very effectively. Because of that, they are excellent at removing coatings from steel tumblers and mugs making a very good looking customized gifts. They can also engrave glass directly with acceptable results.

Cutting performance of CO2 lasers

Cutting planar materials like wooden boards and acrylic plates is where CO2 lasers shine. They are excellent at cutting wood, acrylic (also white and transparent colors), EVA foam, white foam for aircraft model making…

And they can engrave and cut transparent and white plastics just as well as colored ones which is what diode laser cutters were not able to cut.

CO2 lasers usually have shorter focusing range, so they can’t cut as thick like the 40W diode laser modules. Maximum cutting thickness is 10mm to 15mm max for most types of wood, which is still good enough. They also cut cloth and fabrics and leather very easily.

To get a feel for the cutting performance – the 50W Gweike Cloud Pro CO2 laser cuts approximately twice as fast as the 40W xTool D1 Pro which we have tested both.

CO2 laser pros and cons

Pros:

- great for laser engraving business

- much faster at cutting wood and acrylics thanks to better industrial mechanics

- can engrave and cut white and transparent materials too (which diode engravers can’t)

- great for cutting things out of planar material

- self contained unit – has enclosure which enables you to efficiently vent the smoke outside

- safer (because of the enclosure) but not as safe on other hand because the beam is not visible. Always wear safety googles with any laser. None of them are safe for your eyes.

- great for removing paint and coatings from metallic parts

Cons:

- expensive for a hobby

- hard to precisely position engravings on small objects

- can’t engrave stainless steel or any other metals

- vector engravings are harder to get right as it often over burns the corners if you don’t have the settings right

- shorter lifespan of the laser tube (needs to be replaced after few thousand hours of operation) – adds up to the cost

- larger and heavier, not portable

How to make money with CO2 laser cutter

Here is a cool laser cutting business idea: Grab your laser cutter, put in a wood board or acrylic sheet in and cut out boxes, coasters, bowls, candle holders, wedding gifts, wall art, home decorations, pendants, puzzles, RC aircraft parts, animal tags, leather wallets…

Due to high cutting speed you can make wooden stuff in large quantities very fast. A few examples in Etsy shops. You can also sell your laser engraved products there by setting up your own Etsy shop and sell worldwide!

They are not as good at engraving on small objects like pens because it is difficult to precisely position the design. For mass production you can make a template, but for a few pieces it is not as convenient as diode laser.

It can cut and engrave transparent and white materials too which is great for making illuminated transparent acrylic displays like the one below. You can buy the illumination base HERE for cheap.

Galvo Fiber Laser Is Your Best Choice for Engraving Metal

If you only need to engrave on metals an plastics, then a galvo fiber laser is what you want.

Fiber laser machine has a laser source that produces infrared light of 1064nm wavelength just like the xTool infrared module we described earlier. But the laser source is very different. The light is stored in optical fiber and released with high intensity pulses. A 20W fiber laser engraving machine can produce very short pulses in the 10kW power range which instantly vaporize the metal surface. Pulses are produced with high frequency, and because of that it looks like a continuos beam.

Galvo lasers don’t have external moving parts. They have a set of mirrors that direct the laser beam across the working surface. Because of that they have smaller working area, usually around 10cm to 25cm square. They are meant for engraving on small parts VERY quickly and with high precision. They are usually called laser marking machines as they are often used to mark serial numbers, barcodes and other text on products in production line. Since they don’t have moving parts, they are approximately 100 times faster than conventional gantry type of lasers we have described above.

You can read more about Fiber lasers in our ComMarker B4 review article.

Engraving performance of a galvo fiber laser

Fiber laser machines are the best at laser engraving metals of any kind. They easily mark stainless steel, raw aluminum, anodized aluminum, iron, brass, copper, silver, gold, chrome, zinc,… And they can do it FAST.

They can’t engrave wood and similar organic materials whatsoever. This wavelength is not suitable for engraving on fibrous and porous organic material like wood.

Entry level 20W fiber laser engraver can mark metals with speeds more than 10000mm/s (yes, 10 meters per second!) They can engrave a logo or a barcode in a blink of an eye!

Fiber lasers have one more setting than other types of machines and this is frequency. if you want to know more about this setting, read our ComMarker B4 review article. But thanks to having more settings, you can make the engravings darker or lighter on the same material just by adjusting the settings.

Also, these types of laser engraving machines have a very small focus spot, which is 3-5 times smaller than blue diode module or a CO2 laser. Focus spot size is in a range of 0.03mm in diameter. Because of this, they are good at laser engraving VERY small text and precise and intricate vectors. Great for engraving jewellery or small animal tags!

One of the biggest advantages is that they offer a live projected preview of the engraving in real time with harmless eye-safe red light. This way it is very easy to precisely set the location of the engraving on small parts.

Here is an engraving made on crimping pliers. Signature like this is engraving in a split second. It was designed with Kittl.com.

Galvo fiber lasers can also engrave plastics. The engravings can become dark or white depending on settings. If you look around, you will find a lot of plastic products (phone chargers, pens, metal tools, integrated circuits) which were all engraved with a machine like this.

Fiber laser engraver can effectively remove metal from the surface. By setting up multiple passes you can make very deep engravings, up to 0.5mm deep in most metals. The result is amazing and the engraving will never wear off. Ideal for making custom collectible coins!

Cutting performance of a galvo fiber laser

Fiber lasers are not the best cutters, but because they work by actively remove metal from the surface, they can be used for cutting very thin metals in a range up to 0.3mm. But they are not very fast at this and a lot of passes is needed to cut through. But it can be done to make very precise parts from sheet metal.

Galvo fiber laser pros and cons

Pros:

- amazing for large volume laser engraving business

- VERY fast

- can engrave any type of metal

- great at engraving plastics

- can produce very deep and long lasting engravings on metal

- real-time preview with red light – very easy positioning on the workpiece

- great for removing paint and coatings from metallic parts

Cons:

- can’t engrave wood or similar materials

- limited working area

- can’t be used for cutting other than very thin metal sheets

- long lifespan

- rather expensive for a hobby

How to make money with galvo fiber laser

Fiber lasers were ridiculously expensive not so many years ago, and quick technology advancement has made them affordable to hobbyists and smaller businesses too.

Since these lasers are great for engraving on metal and plastic very fast, you can make money by engraving larger quantities of key chains, dog tags, pendants, steel tumblers (if you have rotary attachment), coins, metal business cards, jewellery (jewelry), rings necklaces,… You can also sell your designs by setting up your own Etsy shop!

If you want a reliable supplier for high quality, American-made keychain and animal tag blanks, you should definitely check out guys at Chewbarka.com. They produce all kinds of animal tags and keychain blanks. They also make metal business cards of different thicknesses, luggage tags, slide tags, bottle openers, golf divots and much more. They also supply all the necessary accessories. Definitely check them out they are an amazing team of enthusiasts! If you email them and say that “JT Makes It” sent you, they will give you 25$ of free credit so you can order some samples right away!

Here is a business card engraved with our ComMarker B4 fiber laser:

Each job takes only a few seconds. Most machines also have a foot pedal which is used to start engraving process so you can work fast and have free hands for handling the pieces. If you want to speed up the engraving process for very small items, you can make a jig with your regular diode or CO2 laser to precisely position multiple pieces at once.

But if you want a budget alternative to fiber laser, you can check out something like Enjoywood M4 which we have also reviewed. it is basically something like the xTool infrared laser module mated with a galvo system. It has 10 times less power than a true 20W fiber laser, but it costs less.

Conclusion

Making money with a laser engraver has never been easier and more approachable. If you had trouble deciding on which laser engraver or laser cutter would you need to buy to make stuff to start your laser engraving business, or to add laser engraving services to the products you already make. Diode lasers are great for laser engraving on wood, Fiber laser machine is best for laser engraving on metal. If you are more interested in starting laser cutting business, then you should consider a CO2 laser.

Check our extensive reviews of all these kind of laser machines HERE. And also visit our “Projects and ideas” section where we post different types of stuff that can be made with these machines.

When you get everything going, you should think about creating your own website or use social media sites to market and sell your laser engraving projects and laser engraved items to potential customers across the whole world! The limit is only your imagination! Or maybe you are just wanting to offer occasional laser engraving services to local woodworkers and makers to earn some money back.

Happy laser engraving!

This post was written by JT Makes It.

JT Makes It is an engineer, hobbyist, and DIY-er armed with a Master’s degree in Electrical Engineering and over a decade of professional experience in the industry. From an early age, JT Makes It was pushed by an insatiable curiosity, spending countless hours disassembling, understanding, improving, and creating various gadgets and products. This lifelong passion led to a broad spectrum of technical expertise ranging from electronics, woodworking, metalworking, and CNC machinery, with a particular focus on laser engravers.

For the past 9 years, he has shared his expertise through engaging videos on his YouTube channel. With the last three years dedicated to scrutinizing and testing laser engravers, he also created this website and emerged as a recognized authority in the field. His expertise extends across the spectrum of laser technologies, ranging from diode lasers, CO2 lasers, and fiber lasers, paying attention to details and providing practical insights.

With JT Makes It, expect a blend of technical expertise, backed with hands-on experience, and a genuine passion for innovation and creation, making him a trusted source in the realm of DIY and laser engraving enthusiasts alike.

May I get more information?